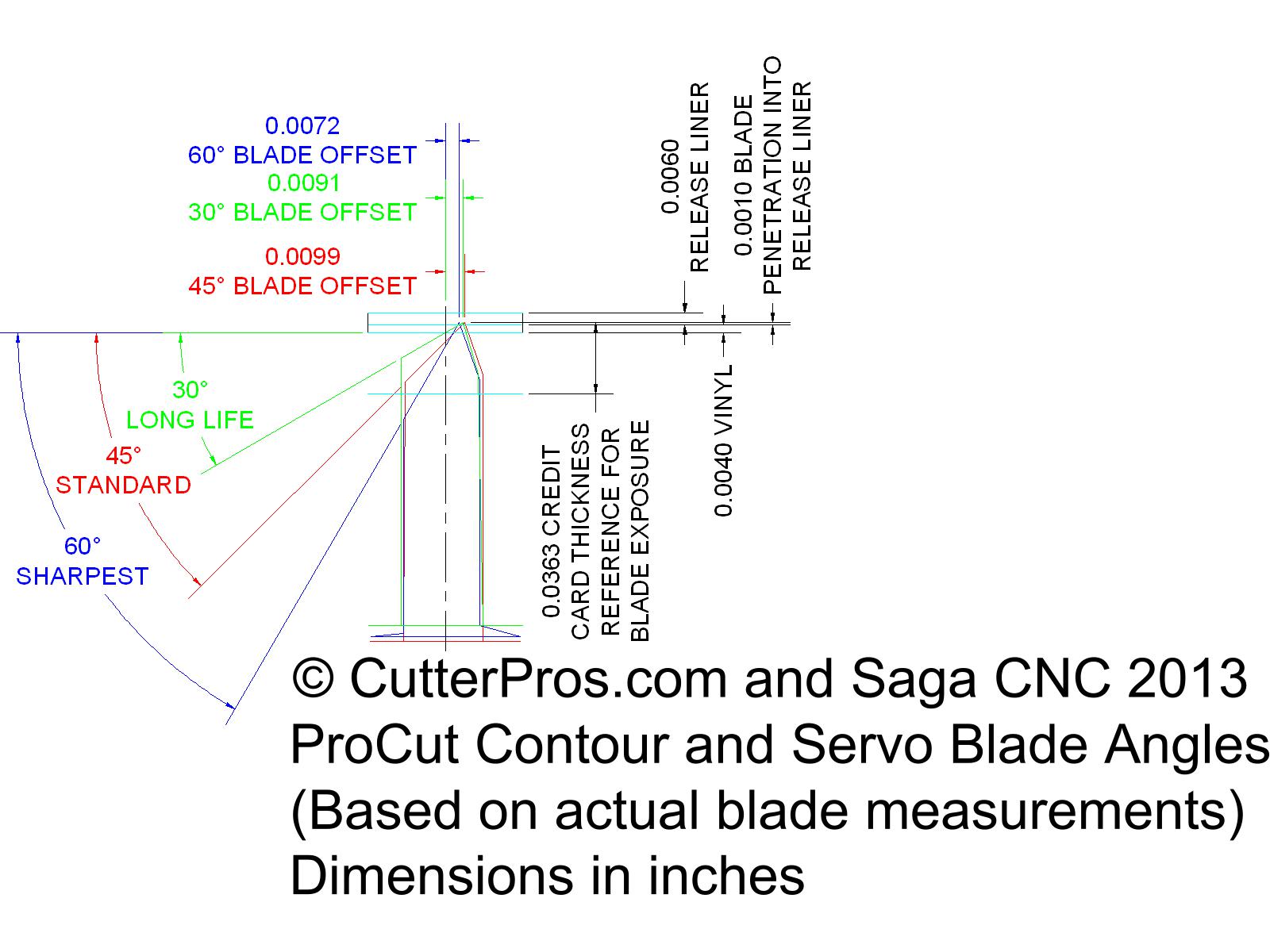

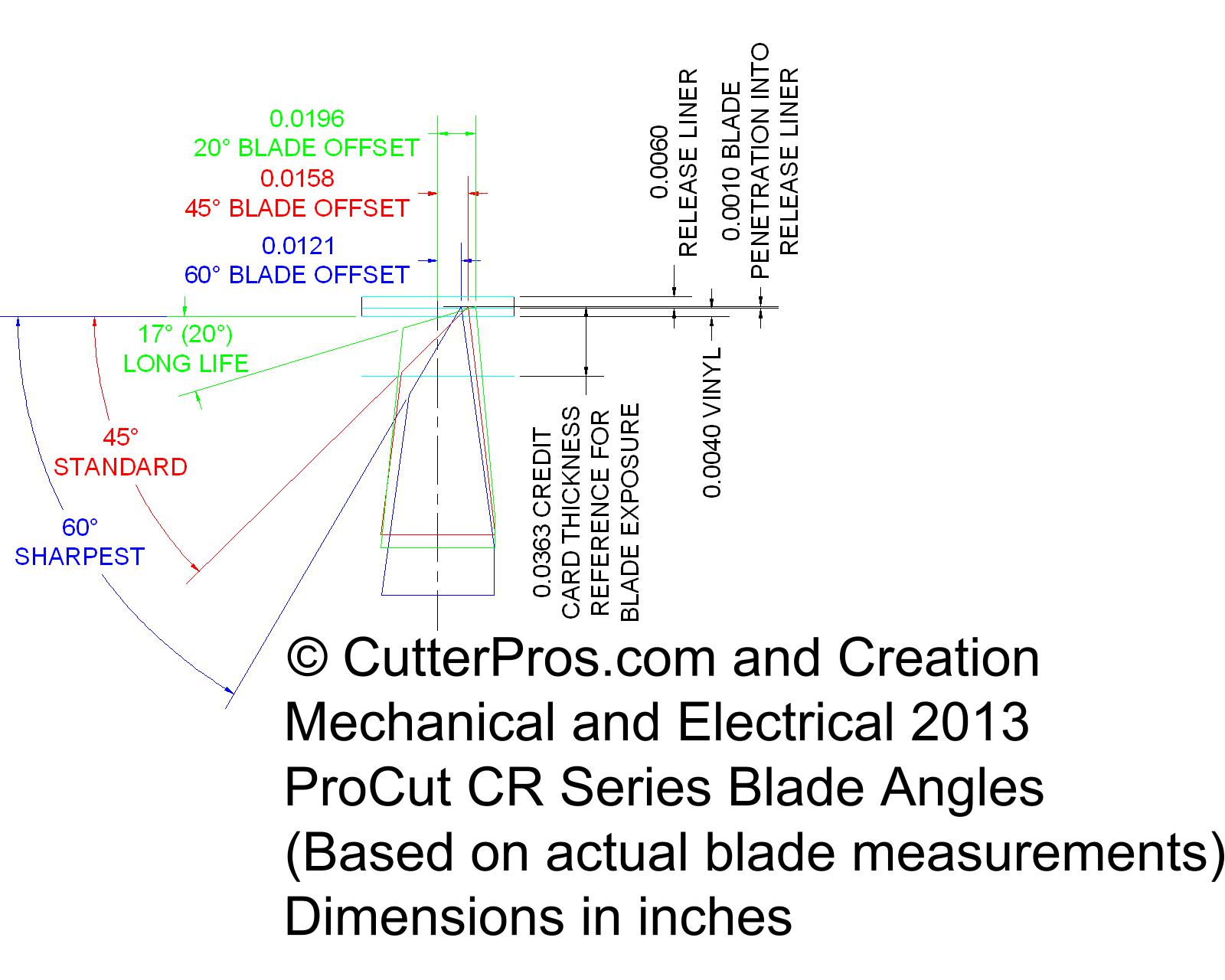

Your vinyl cutter operates based on a drag knife system. This means that the actual cutting that your blade is doing happens behind the centerline of rotation of the blade shaft. Your blade holder restrains the blade with a magnet. As your vinyl cutter pulls the blade center along, the point of cut trails the center by a distance that is dependent on the blade angle but is approximately .008″ (for a Contour or Servo cutter). This means that when the vinyl cutter tries to make a sharp corner, it will need to travel beyond the end of the corner by the blade offset distance and then rotate down to the next vector to continue pulling the blade. Flexi and SignCut do this regularly as a function of the blade offset that you enter into these programs. If you have 0 in for the blade offset, the corners will be rounded. If your blade offset is too high then your corners will have a lip. Getting the blade offset correct for the blade you are using is essential for good quality corners.

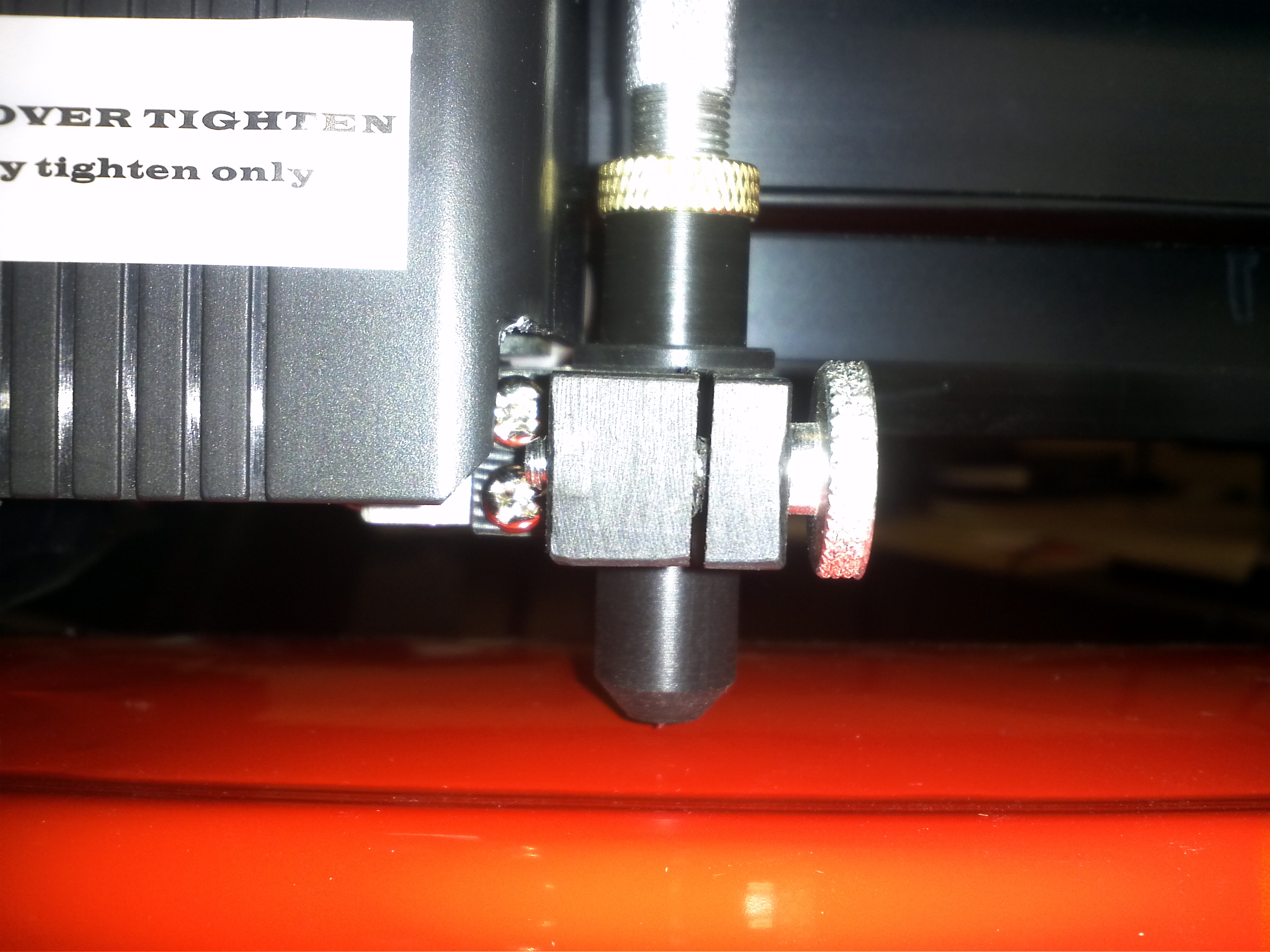

Blade penetration into the vinyl is based on force, not on depth and not by the blade holder cover. If your blade holder cover is too close to the vinyl it will scratch up the surface. There should be approximately the width of a credit card from the tip of your blade to the beginning of the blade holder cover. (see pictures)

Below you will find blade offsets as measured for ProCut Contour-Servo series blades as well as CR series blades.

Leave a Comment

You must be logged in to post a comment.